RadalyX Applications

A wide range of applications, all at micrometric level in 2D or even 3D image.

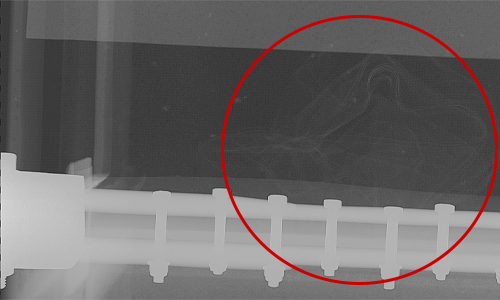

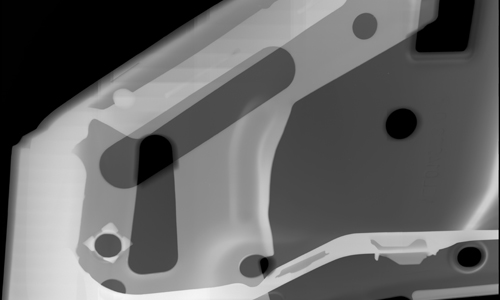

Aerospace

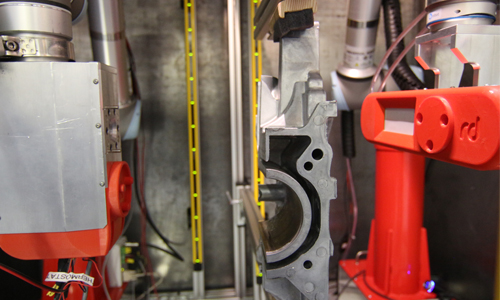

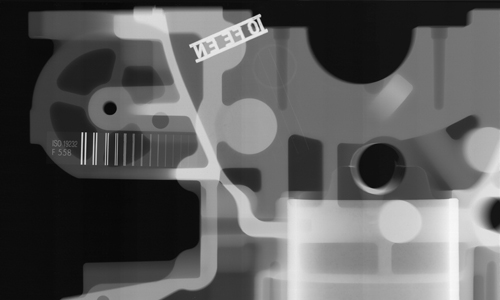

Automotive

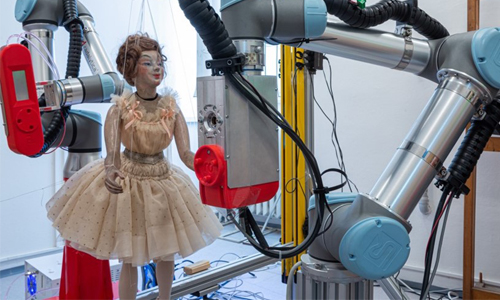

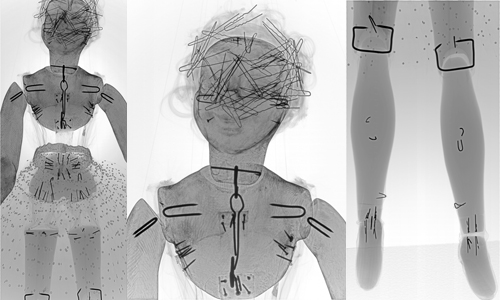

Art

Medical field

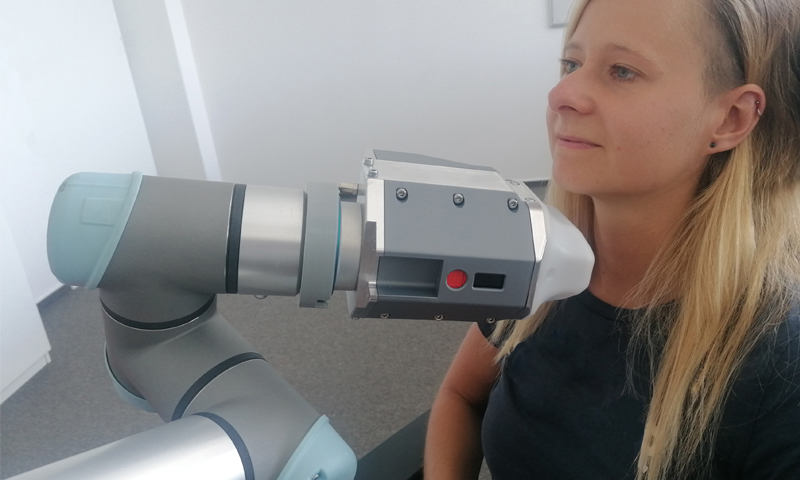

ThyroPIX Project

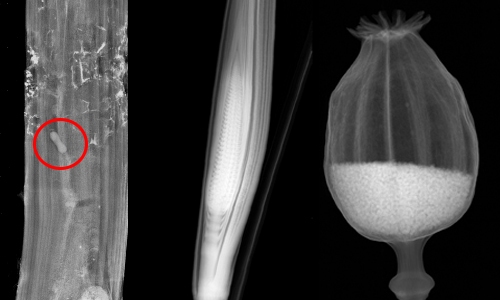

The new generation mobile robotic imaging camera prototype for thyroid gland and small organs imaging

On the way into medicine

Robotic Computed Tomography - robots in the movement of the medical imaging future

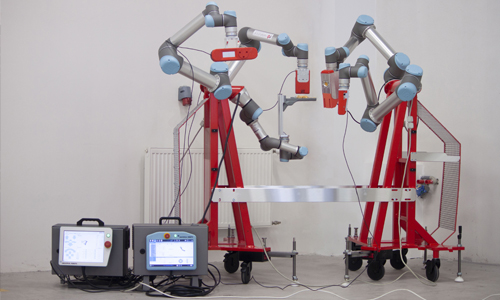

The robotic scanner for purposes of research on cancer treatment with ion beams on small animals (mice or rats)

Read More...